Sold out

Sold out

Fiberlay | SKU:

F-153P241

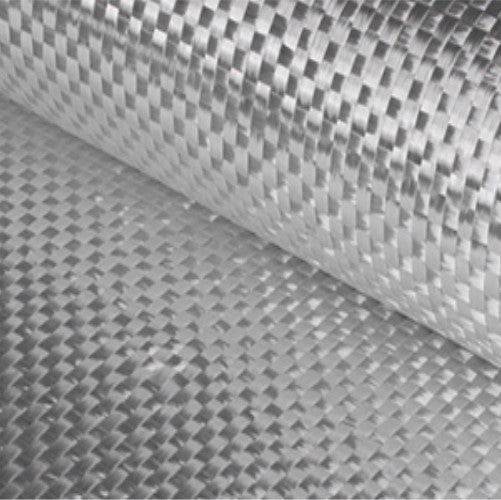

Fiberlay 24oz Woven Roving Fiberglass Mat

Regular price

$12.99 CAD

Unit price

/

Unavailable

Fiberlay 24oz Woven Roving Fiberglass Mat - 1YD x 38" (Packaged) is backordered and will ship as soon as it is back in stock.

Ships By Sat, December 20

Free

Canada Shipping over $120

Couldn't load pickup availability

Woven Roving is made up of bundles of unidirectional fiberglass filaments woven into a course heavy weave fabric used in fiberglass laminates to produce modulus and tensile strength through bulk and weight. The sides of the material in the warp direction have a stitched edge to prevent unraveling. Woven roving is generally used as part of a lay-up schedule alternatively with chopped strand mat to achieve the desired thickness and strength. Due to the course woven characteristic, this material will use proportionately more resin to wet out. Used alternately with chopped mat improves glass to resin ratios.

-

BrandFiberlay

-

SKUF-153P241

-

TypeFiberglass Material

-

Barcode648728002793

Fiberlay 24oz Woven Roving Fiberglass Mat Reviews

Customer Reviews

Be the first to write a review

0%

(0)

0%

(0)

0%

(0)

0%

(0)

0%

(0)